| Business Type | Manufacturer, Exporter, Supplier, Distributor |

| Country of Origin | India |

| Packaging Size | 25-50 Kg |

| Application | Rubber Product Manufacturing |

| Click to view more | |

Product Details

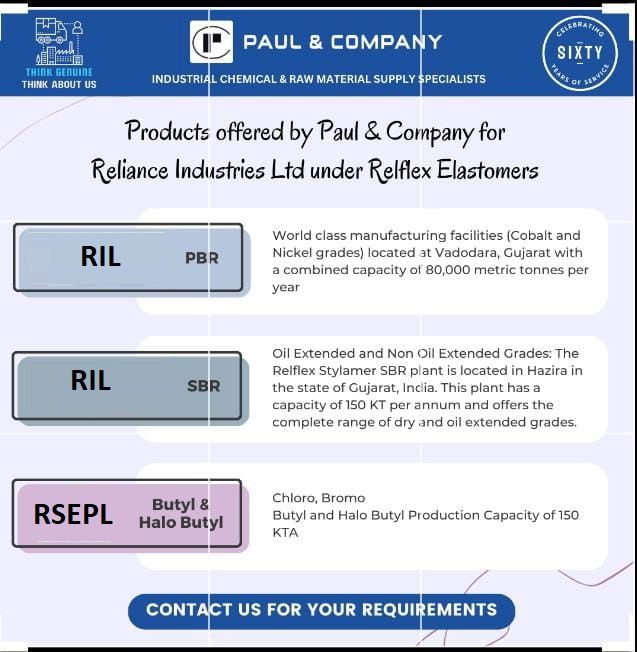

We as a renowned Supplier of Reliance Styrene Butadiene Rubber(SBR) strive to meet your exact needs with precision. Reliance Styrene Butadiene Rubber(SBR) is equipped with features such as low rolling resistance, enhanced abrasion resistance and versatility that make it the highest consumed rubber round the globe. SBR is sourced from the plant located in Gujarat, India having capacity of 150 KT per annum. It is integrated with the captive butadiene feed that is extracted from the petrochemical complex, which is on site. It is largely used for passenger car and light truck tyres and truck tyre retreads, conveyor belts, shoe soles, V-belts, molded rubber goods and in the manufacturing of extruded gaskets, hoses, brake & clutch pads, automobile mats, flooring, rubber toys, food packaging, adhesives and chewing gum.

Details :

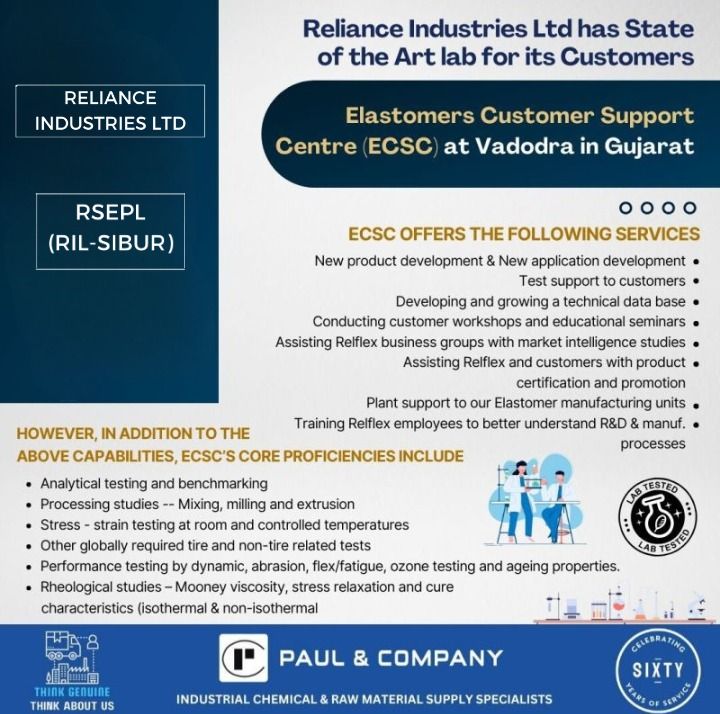

- Paul & Company is representing Reliance Synthetic Rubber Elastomer for Reliance Industries Limited.

- Stylamer is emulsion grade Reliance Synthetic Rubber Elastomer (SBR) from Relflex’s elastomer range. SBR is one of the highest consumed synthetic rubbers in the world due to its versatility, enhanced abrasion resistance and low rolling resistance.

- E-SBR is a versatile product and is used in wide spectrum of application.

- Some of the major applications of E-SBR include passenger car and light truck tyres and truck tyre retreads. It is also preferred in applications such as conveyor belts, shoe soles, V-belts, moulded rubber goods etc. It is also extensively used in the manufacture of other products such as extruded gaskets, hoses, brake & clutch pads, automobile mats, flooring, rubber toys, food packaging, adhesives and chewing gum among others.

Properties and Applications

| Relflex Stylamer | Mooney Viscosity ML(1+4) @ 100°C, MU |

Bound Styrene, % |

Oil, PHR | Oil Type | Key Features | Applications | |

| SBR 1500 | 52 | 23.5 | - | - | Good tack & slightly slow curing | Tyre & conveyor belt | |

| SBR 1502 | 52 | 23.5 | - | - | Good processibilty & abrasion | Tyre, footwear & mechanical rubber goods. | |

| SBR 1509 | 33 | 23.5 | - | - | Enhanced processibility & easier incorporation high filler loading | Footwear, microcellular sole & injection molded article. | |

| SBR 1712 | 51 | 23.5 | 37.5 | DAE | Easier incorporation of filler-maintaining good processability | Tyre, conveyor belt, hose & mechanical rubber goods. | |

| SBR 1721 | 54 | 40 | 37.5 | DAE | Excellent road grip & good processability | Tyre tread (high performance type) | |

| SBR 1723 | 48 | 23.5 | 37.5 | TDAE | Alternative to SBR 1712, lower rolling resistance | Tyre, conveyor belt, hose & mechanical rubber goods | |

| SBR 1739 | 52 | 40 | 37.5 | TDAE | Alternative to SBR 1721, better processing behaviour & improved abrasion resistance | Tyre tread (high performance type) | |

| SBR 1778 | 49 | 23.5 | 37.5 | Napthenic Oil | Alternative to SBR 1712, Good processability & easy incorporation | Footwear, hoses, light colored goods & floorin | |

Looking for "Reliance Styrene Butadiene Rubber(SBR)" ?

Explore More Products